PRODUCT

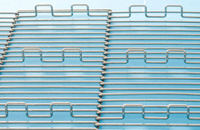

Uni-Flex Wire Belt

- Uni-Flex Wire Belt

-

LARGE OPENING

Gives better air flow through in both heating and cooling process.

-

SMALL ROLLERS

Rollers in small diameter help tight transfer.

-

EASY to CLEAN UP

Washing away residues easily and Excellent in removing germs.

-

SPROCKET DRIVE

Direct sprocket drive avoid slipping and lateral displacement.

- Large Openings

- Uni-Flex wire belt has extra large opening and gives better air flow through. Cold/cool air or hot are not shut by belt and directly reach objects. So, many use in cooling lines and heating lines are able to considered.

Pictures are examples – Deep fried fish coming out of fryer; products just coming out of fryer is still in high temperature. Thus, stainless steel would be the best option. - Small Rollers

- Small rollers can travel product smoothly at the same level. As shown by the picture, very soft and small object can transferred. The size of transfer roller in th picture is 20mm in diameter, which enables very tight transfer.

- Easy to Clean Up

- Due to large openings, less residues (fragment of product) is stuck and stayed on the opening of wire belt. In comparison with other type of wire belt, It is easy for Uni-Flex wire belt to remove product waste from the belt. This could be a clue to hygienic solution.

- Direct Sprocket Drive

- Direct sprocket drive can run the belt with less lateral displacement. Sprocket teeth are firmly engaged with wires and no slip will be happened. Sprocket position can be considered HEAD DRIVE a picture shown or CENTER DRIVE; drive position placed bottom of conveyor.

Usage

Uni-Flex Wire belt is designed for

- Chocolate Enrobing, Battering, Breading, Heating, Frying, cooling, Freezing, Film-shrink packing in food processing lines.

- Cleaning System for electric device and automobile parts in soldering, particle control in metal cutting and stamping factories.

Typical Size and Usage

| 0.9mm wire dia. x 6mm pitch | Chocolate coating, sugar or dry powder dusting |

|---|---|

| 1.2mm wire dia. x 7mm pitch | Small product cooling, sorting and washing |

| 1.6mm wire dia. x 7.3mm pitch | Fryer, Steamer, Loose product carrying |

| 1.8mm wire dia. x 12.7mm pitch | Oven, Shrinking machine, Printed circuit board washing and drying |

| 2.3mm wire dia. x 12.7mm pitch | Plastic or metal stamping products washing, Plastic molded product annealing |

| 3.0mm wire dia. x 20mm pitch | Chiller, Freezer |

| 3.5mm wire dia. x 20mm pitch | Bulky products washing and drying |

The available specification is more than the mentioned above. Please let us know your request specification. Please refer to "Measuring Specification" if you are not sure about request specification.

Uni-Flex wire belt with Flight

With wire rod splicing construction, Uni-Flex wire belt is flexible to equip with variety of flight to help product alignment, supporting products on inclined conveyor or holding by point contact.

|

|

|

|

Sprockets

We, as manufacturer of wire belt, can also offer suitable sprocket made of either plastic (POM) or Stainless Steel for the best engagement.

|

|

Uni-Flex Curve Belt

It is required to combine curve conveyor with straight conveyor for better layout of full automation line. We offer 90 and 180 degree curve belt for standard specification.

|

|

|

|

Complete conveyor system is also available to offer, if requested.

Download of PDF fileUni-Flex Curve Belting and Conveyor System(PDF/10.5KB)